Metal Fabrication

Sheet Metal Cutting & Punching

Our flagship Amada CNC Fibre Lasers have the power and accuracy to cut parts from sheet metal up to a sheet size of 4m x 2m and a material thickness of 25mm. Through our Laser / Punch combination machine, we are able to cut and punch formed holes on a single machine which reduces our customers’ cost per unit. The same machine can also tap holes which further compounds this benefit.

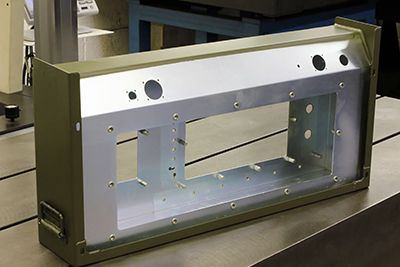

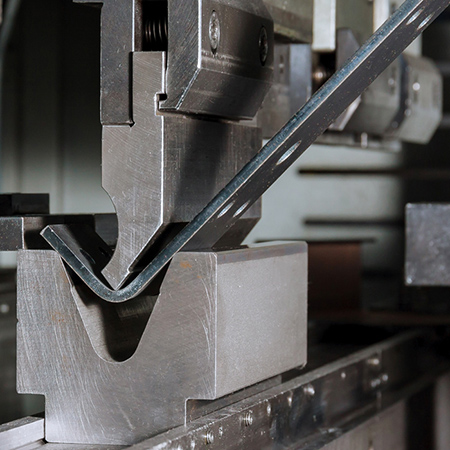

Bending and Forming

Using a fleet of 5 CNC brake presses parts get bent to a variety of angles utilising a range of radius dies and stamps to form custom flanges, lips, panels and enclosure shapes. Through the maintaining of tight tolerances our parts are made to drawing, and our assemblies consistently fit together as they should.

Welding

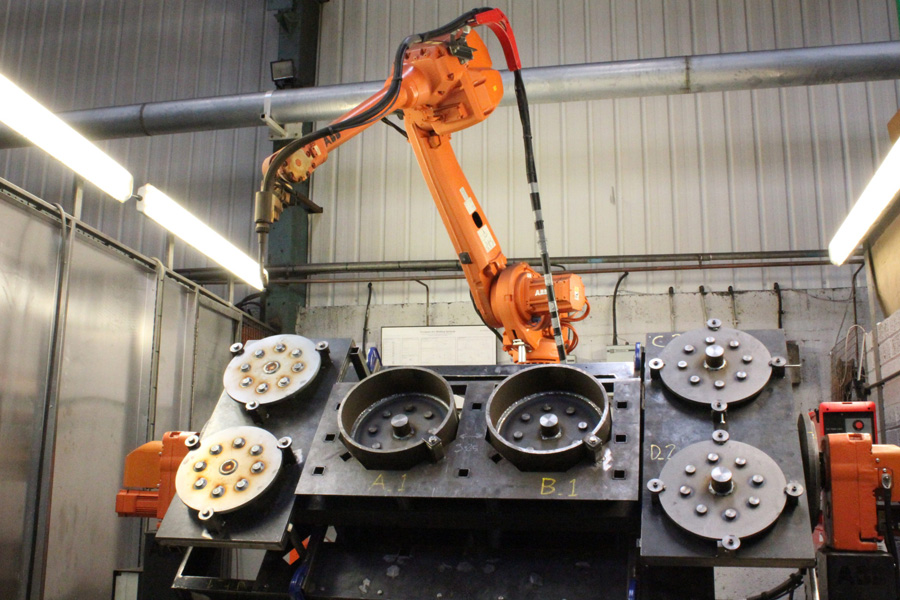

For smaller batch runs and prototyping we utilise our 13 welding bays for the TIG & MIG welding of parts. For production work our Robot Welding cells drive down customer costs through offering welding efficiency and scale. Additionally, we have spot welding and projection welding capability which gets used for such things as weld nuts and studs.

Design

Skilled designers take our customers’ technical drawings and 3D models to create manufacturing drawings. These fully detail the necessary material specifications, dimensions, bend angles, hardware requirements, and any other manufacturing instructions required for the project.

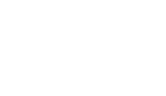

Machining

Through a number of machining operations, we are able to complete the full fabrication requirement. This includes milling, turning, drilling, inserting and grinding. These operations create holes and features for hardware attachment points, rapid installation, airflow, cabling access or fixturing positions. This delivers customer parts ready for integration and end use.

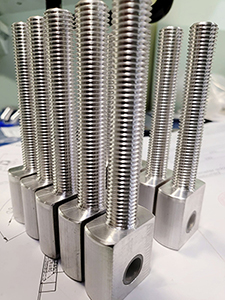

Finishing & Coating

For the welded parts we have a dedicated fettling area where we are able to prepare the parts and assemblies for surface coating. If our customers do not have in house finishing, we are able to clean, paint, powder coat, galvanize, electroplate, anodize, metal coat and passivate to meet the finished part requirements.

Fabricated Parts & Assemblies

Our Machinery

PUNCH LASER

Amada EML punch/laser combination with tower loader.

LASER

Amada ENSIS Fibre Laser 4000 x 2000 laser with tower loader.

BENDING / FORMING

MANUAL MIG/TIG

Fronius CMT Welding Equipment

ROBOTIC WELDING

ABB robotic welding cells x3 and Fanuc robotics welding cells x6

DEBURR

DiscMaster 4TD 1500mm Deburring/Edge Rounding

SAW

Prosaw and Behringer Automatic Saws

SPOT WELDING

Meritus Spot Welder:

INSERTING

Pemserter 2000 with Auto Loader:

ROLLING

3m Powered Rolls

Get in touch to discuss your metal fabrication project.